When designing an underground drainage or utility system, it’s important to know the difference between manhole and inspection chamber. Both are ways to get in. but they are different sizes, have different purposes, and need different kinds of structures.

Govind Steel, a leading cast iron manufacturer, makes high-strength castings. All that are widely used in municipal and industrial infrastructure. This makes them a trusted name among manhole foundries in India.

Let’s look at the differences between manholes and inspection chambers, also, how each one is important for underground systems.

What Is A Manhole?

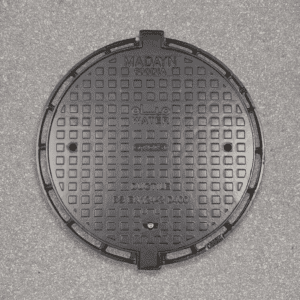

A manhole is a deep, vertical opening that lets workers get into underground networks to fix, to clean, and check them, as manholes are made to hold heavy loads and let people in, to clean. Especially in roads and industrial areas, where strong construction is needed.

Where Manholes Are Used

- Roads, highways, and business districts

- Systems for draining stormwater and sewage

- Utility networks include things like communication lines, cables, and pipelines

- Places where the direction, slope, or size of the pipe changes

Most manholes have strong cast iron covers on them. Companies like Govind Steel make high-performance castings that are made just for these tough jobs.

What Is An Inspection Chamber?

An inspection chamber, also known as an access chamber, is a smaller, shallower structure used to reach pipelines with tools or cameras. Unlike manholes, inspection chambers are not intended for human entry.

Where Inspection Chambers Are Used

- Roads, highways, and business districts

- Sewers and stormwater drainage systems

- Utility networks include things like communication lines, pipelines, and cables

- Changes in direction, slope, or pipe size

Most of the time, manholes have strong cast iron covers on them. Companies like Govind Steel make high-performance castings that are made just for these tough jobs.

Key Differences Between Manhole And Inspection Chamber

1. Depth And Size

Manholes are deep structures, often several feet below ground, allowing technicians to climb inside. Inspection chambers are shallow. And, usually up to 1 meter deep, suitable only for tool-based checks.

2. Purpose Of Installation

Manholes: Made so that people can get to important utility lines.

Inspection chambers: These make it easy to get to for cleaning, checking, and small repairs.

3. Load-Bearing Capacity

This is one of the biggest distinctions. Manholes, especially those on roads, have to be able to handle a lot of weight from cars. This is why trusted Indian manhole foundries like Govind Steel make heavy-duty cast iron covers.

Inspection chambers have lighter load requirements. Since they are typically installed in non-traffic areas.

4. Materials Used

Manholes need cast iron parts because:

- Strong tensile strength

- Very good at holding things up

- Over time, it doesn’t rust

Govind Steel is one of the best companies that makes cast iron. All of these are used in both public and private infrastructure.

It depends on where they are and how they are used. The inspection chambers might use lighter materials, but they still need to be built well so they last.

5. Location And Placement

Manholes: Installed at major pipeline junctions, changes in slope, direction, and at regular intervals to allow maintenance workers access.

Inspection chambers: Installed closer to the surface, usually, at points where frequent visual checks are needed.

Why The Distinction Matters

Choosing the wrong structure can lead to system failures. Also to safety hazards, and costly repairs.

For Example

- Placing an inspection chamber in a high-traffic area can lead to collapse.

- Using a manhole where only small inspections are needed, and they can increase project costs unnecessarily.

Infrastructure planners and contractors depend on reliable cast iron components, which is why established manufacturers like Govind Steel remain essential to large and small projects across India.

Final Thought

Understanding the Difference Between Manhole and Inspection Chamber is crucial for designing safe, efficient, and long-lasting underground systems. While manholes provide full access for heavy-duty maintenance, inspection chambers offer simpler, tool-based entry for routine checks.

Both structures serve unique functions and must be chosen, based on location, load requirements, and maintenance needs. Along with high-quality cast iron parts from trusted Manhole foundries in India. Like Govind Steel, infrastructure projects can achieve superior strength, reliability, and long-term performance.

Choosing the right component today ensures smoother operations. It also reduces maintenance costs in the future.

FAQs

Are inspection chambers and manholes the same thing?

No, people can go into manholes. But inspection chambers are only meant for tools to check things.

Which one is more powerful?

Manholes are much stronger because they are made of heavy-duty cast iron and have to hold up under heavy traffic.

Where should you put inspection chambers?

They work best in residential areas, gardens, and places with little traffic where only quick inspections are needed.

What makes cast iron better for manholes?

Cast iron is very strong, long-lasting, and resistant to rust. These are all important qualities for underground infrastructure.

Who makes long-lasting parts for manholes in India?

Govind Steel is one of the most trusted names in India. Mostly, when it comes to manhole foundries.